dual side sealers for paper and poly

Dual Side Sealers for Paper and Poly

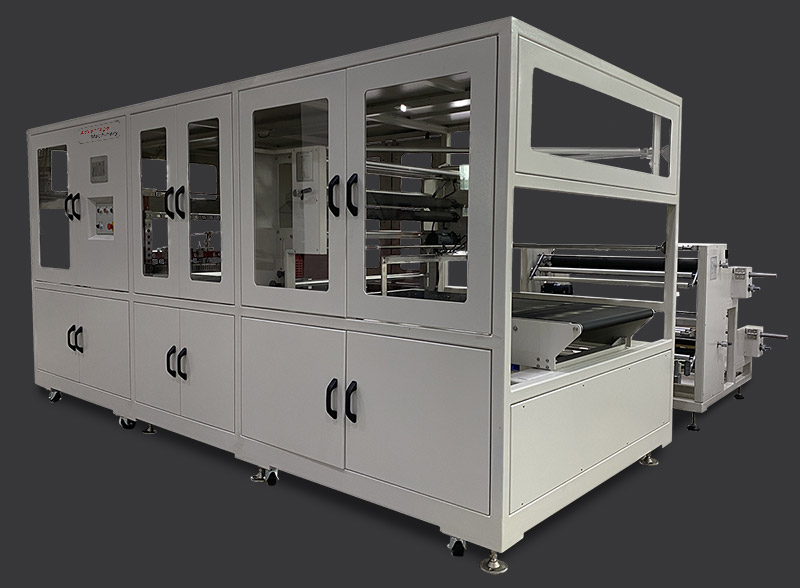

The Advantage Machinery DSS is the newest development from Garrido. The DSS is a fully automatic, continuous motion side sealer specialized in the sealing of treated paper and poly.

The machine comes standard with 6' infeed conveyor. The paper is fed on the unwind stand using a dual roll carriage and its passes through an inverting section into the seal area. The product is introduced into the machine through the infeed conveyor. The spacing conveyor detects the leading and trailing edges of the product in order to create the appropriate spacing. The side seal systems seal the lateral sides of the products, and the trim gets suctioned away in the vacuum system. After the sides are sealed, the continuous motion cross seal section seals and cuts the paper between each product.

The machine can come in a variety of widths and can also come with a sealing kit to enable sealing both paper and PE.

Imperial (in)

Metric (mm)

A D D I T I O N A L I N F O

DSS-80P, DSS-110P

SPECIFICATIONS

Dual Side Sealers for Paper and Poly

The Advantage Machinery DSS is the newest development from Garrido. The DSS is a fully automatic, continuous motion side sealer specialized in the sealing of treated paper and poly.

The machine comes standard with 6' infeed conveyor. The paper is fed on the unwind stand using a dual roll carriage and its passes through an inverting section into the seal area. The product is introduced into the machine through the infeed conveyor. The spacing conveyor detects the leading and trailing edges of the product in order to create the appropriate spacing. The side seal systems seal the lateral sides of the products, and the trim gets suctioned away in the vacuum system. After the sides are sealed, the continuous motion cross seal section seals and cuts the paper between each product.

The machine can come in a variety of widths and can also come with a sealing kit to enable sealing both paper and PE.

Imperial (in)

Metric (mm)

MORE dual side sealers for paper and poly EQUIPMENT